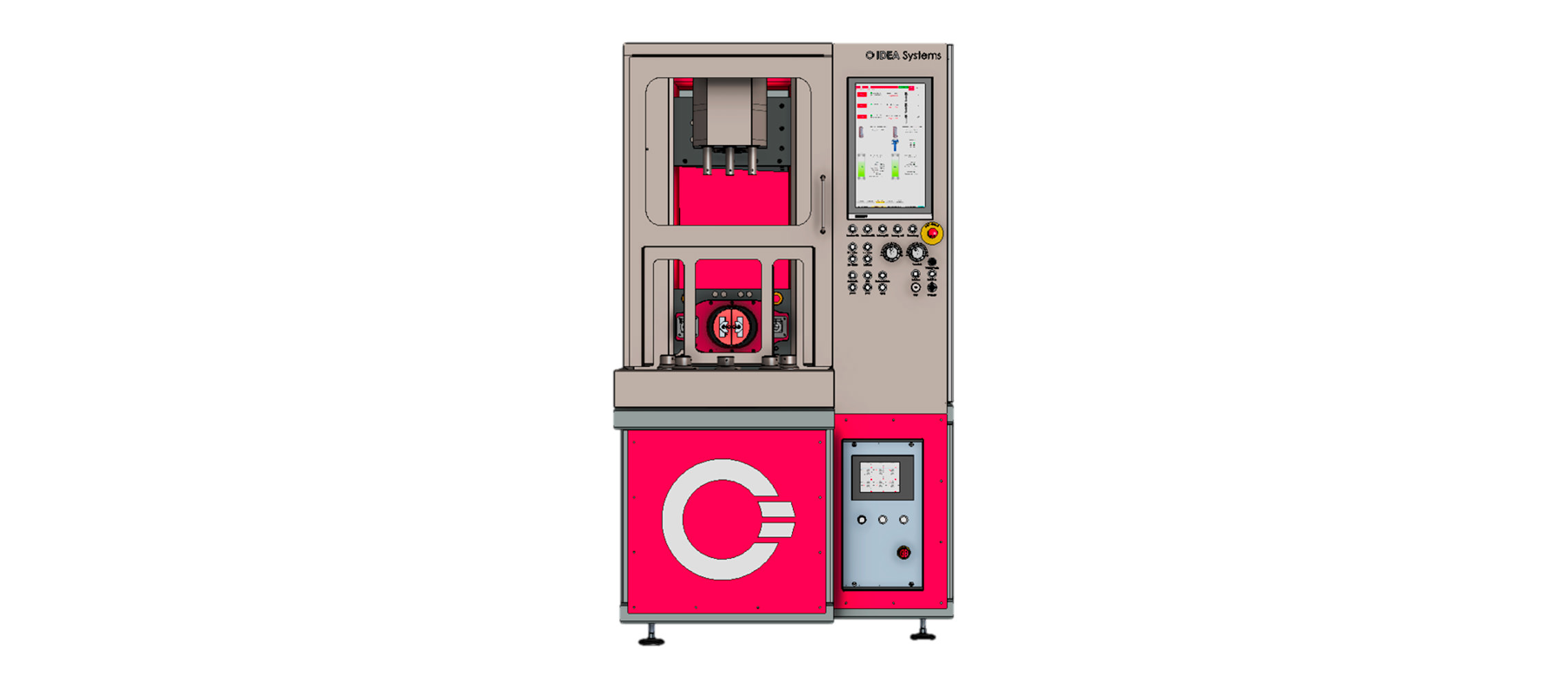

Ultra Compact Hardening Machine KH500

KH500 Areas of application

- Contract hardening shops: For a wide range of workpieces

- Car: Powertrain, transmission, engine,...

- Truck: Engine, brake system, components...

- Engine construction: Camshafts, cams, rocker arms, valves, shafts,...

- Gear construction: Gear wheels, hollow shafts, racks, bolts...

- Power generation/supply: Bolts, contacts, special parts High voltage,...

- Construction machinery: Bolts, ...

- Aerospace: Screw hardening and tempering, turbine wheels,...

- Bearing industry: Large/small bearings, special bearings, rails, carriages,...

- Two-wheel industry: Hubs, shafts, electric motor parts, bottom brackets,...

- Agricultural implements: Knives, tines, bolts, ...

- Mechanical engineering: Ball cups/heads, shafts, gear wheels, piston rods,...

- Textile industry: Bobbin holders, rolls,...

- Fastening technology: Screws, sleeves, bolts, rivets,...

- Drive elements: Ball screws and their nuts, piston rods,...

- Tools : Drills, clamping devices, splitting tools, ...

- Universities and institutes: Testing machine for a wide range of applications

Features of the ready-to-use machine KH500

- CNC control Beckhoff already prepared with 5 axes

- Tailstock and second station drive as options (before or after the heating station)

- Manual loading also in a sitting position

- Automation optionally possible

- Control cabinet and inverter on the machine frame

- Ultra-compact dimensions, can be moved and positioned with forklift / crane

- After aligning the machine and connecting the media (energy, cooling water, quenching medium and air), the machine is ready for operation.

- Switch cabinet cooling as standard

- Inverter 30kW high or 50kW medium frequency as selectable standard (other induction inverters in separate design possible on request)

- Status display integrated as RGB diode bar

- Hardness length up to 500 mm, component weight up to 5 kg

- Stainless materials in the wet area of the machine

- Roller blinds to separate the wet from the dry area of the machine

- Rotary indexing table for single and double station operation, CNC rotary drive in the hardening station

- Hardening directly in the hardening station even without rotary indexing function

- Beckhoff CNC control with 18-inch full HD touchscreen

- Process data storage and remote connection through Windows system, connection machine prepared via LAN, possible via WLAN

- Clear and concise operating structure

- Operator release levels by key switch

- CNC programme structure on DIN basis